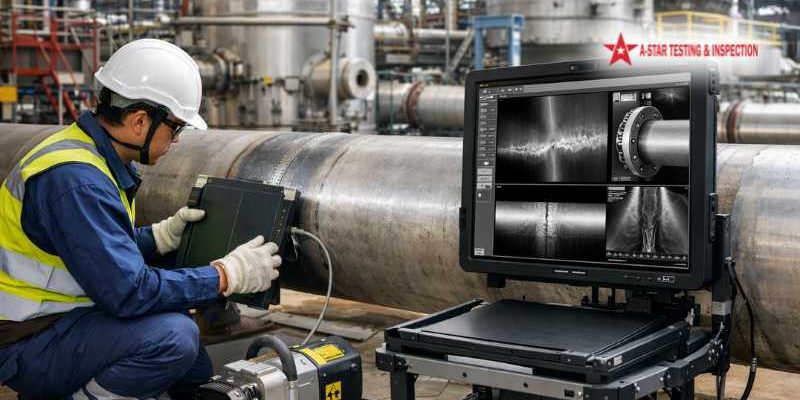

The welds, pipelines, and industrial equipment that are used in high-stakes industries such as oil and gas, petrochemicals, and power plants should have the welds, pipelines, and equipment accurately inspected. Computed Radiography & Digital Radiography (CR & DR / CRT & DRT) services offer fast, precise, and non-destructive testing (NDT) solutions, which can assist companies in ensuring the integrity of materials, yet comply with the ASME, API, and ISO standards.

Through the use of modern digital X-ray inspection, our certified technicians introduce high-resolution radiography testing services that significantly decrease the exposure time and dispense with the chemical-film processing.

Service Scope Disclaimer: We are CR/DR strictly land-based and topside only. Our services are not underwater or subsea radiography services.

What Are Computed Radiography & Digital Radiography Services?

Whereas radiography used to be based on film, the CR and DR radiographic procedures, with the use of digital sensors, capture and analyze information immediately.

- Computed Radiography (CR / CRT): It is a technique that employs special imaging plates (IP) to record the X-rays. The plates are then scanned in a digital scanner to create a high-resolution image.

- Digital Radiography (DR / DRT): It involves the use of flat-panel detectors (FPD) to generate images instantly on a computer monitor in real-time, the quickest turnaround inspection in the business.

These are critical technologies required in the weld radiography inspection processes, pipeline radiographic testing, as well as pressure vessel testing in the fabrication yards and refineries of Malaysia.

Core Computed Radiography Services (CR / CRT)

CR cassette radiography. Our CR cassettes radiography solutions are perfect for field applications, with portability being central to these applications.

- High-Resolution Imaging: The ability to capture small details in complicated welds and joints.

- Image Plate Processing: This is an advanced scanning to digital format, which allows better manipulation and zooming of the X-ray exposure.

- Portable Computed Radiography Services: This is optimized to be used on-site to have minimal effects on the operations.

Core Digital Radiography Services (DR / DRT)

Our Digital Radiography(DR) systems are designed to provide unprecedented speed where the production volume must be high, and safety checks are absolute.

- Flat Panel Digital Radiography: Real-time capture, which will be immediately analyzed by NDT specialists.

- Real-Time Digital Radiography: The defects are detected immediately when they occur, and a decision can be made instantly on whether to repair or pass that item on the shop floor.

- DICONDE-Compliant Reporting: The ability to ensure that all digital deliverables are in place and comply with international standards regarding archiving and audit traceability.

Applications and Industry Benefits

Our radiography testing, in relation to industrial services, serves the most challenging industries in Malaysia:

- Oil and Gas: Checks made on the pipeline girth welds and the integrity of the storage tanks.

- Petroleum Chemical Plant: High-pressure piping and reactor vessel quality assurance.

- Power Generation: Radiography of boilers, steam lines, and heat exchangers.

- Fabrication: Structural verification of stainless steel, carbon steel, and duplex alloys.

Key Advantages of Digital NDT:

- Reduced Radiation Zones: The less the radiation time, the safer the area becomes for the workers.

- Environmentally Friendly: No hazardous chemicals or silver waste from film processing.

- Improved Flaw Detection: Digital instruments can be adjusted to contrast to locate cracks, porosity, and slag that can be missed by a film.

- Quick Turnaround: DR takes less time compared to RT because the results are obtained in real-time, thereby cutting the inspection time by half.

Frequently asked questions: CR and DR Radiography Services.

Q1: How are CR and DR different?

Ans: CR (Computed Radiography) is a two processes in which an imaging plate will be required to be scanned. DR (Digital Radiography) is a single-step procedure whereby the images are transmitted immediately to a monitor.

Q2: Do digital radiography services meet ASME and API?

Ans: Yes. Our services are compliant with the ASME Section V and API 1104 requirements, with fully compliant digital reports for all industrial projects.

Q3: Offshore topsides, is it possible to use these services?

Ans: Absolutely. Although we do not carry out underwater work, our CR and DR teams are well-trained in the topside offshore inspections of platforms and the FPSOs.

Q4: How does DR improve safety?

Ans: Digital detectors are superior to film in that we can work with reduced strength of radiation sources or reduced exposure time, and the radiation safety perimeter is greatly reduced.

Conclusion: Digital Radiography Asset Integrity Modernization.

Computed Radiography & Digital Radiography (CR & DR / CRT & DRT) services are crucial to modern industrial inspection in Malaysia, as they are accurate, safe, and compliant. Using the very best digital X-ray technology, facilities will avoid asset loss, decrease maintenance time, and have quality audit-ready documentation.

Contact A-Star Testing & Inspection Today to arrange a consultation on your next project of CR & DR radiography.